Researchers at MIT and elsewhere have developed a supercapacitor that uses no conductive carbon at all, a breakthrough that might potentially produce more power than existing versions of this technology.

In the process, they've developed the first example of a class of electrically conductive material called "metal-organic frameworks" (MOF), opening up the possibility for more durable and higher-performance supercapacitors because of this material's relatively high surface area.

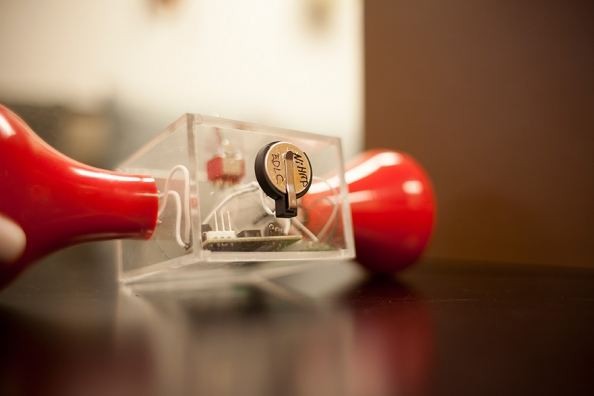

Called Ni3(hexaiminotriphenylene)2, the new material allowed researchers to create the first electric double-layer supercapacitor without conductive carbon.

The team's findings were reported in the journal Nature Materials, in a paper by Mircea Dincă, an MIT associate professor of chemistry; Yang Shao-Horn, the W.M. Keck Professor of Energy and four others.

"We've found an entirely new class of materials for supercapacitors," said Dincă.

For years, Dincă and his team have been exploring MOFs, which are extremely porous, sponge-like structures. These materials have an extraordinarily large surface area for their size, much greater than the carbon materials do.

That is an essential characteristic for supercapacitors, whose performance depends on their surface area. But MOFs have a major drawback for such applications.

They are not very electrically conductive, which is also an essential property for a material used in a capacitor.

"One of our long-term goals was to make these materials electrically conductive," noted Dincă, even though doing so "was thought to be extremely difficult, if not impossible."

But the material did exhibit another needed characteristic for such electrodes, which is that it conducts ions (atoms or molecules that carry a net electric charge) very well.

"All double-layer supercapacitors today are made from carbon. They use carbon nanotubes, graphene, activated carbon, all shapes and forms, but nothing else besides carbon. So this is the first noncarbon, electrical double-layer supercapacitor."

One advantage of the material used in these experiments, technically known as Ni3(hexaiminotriphenylene)2, is that it can be made under much less harsh conditions than those needed for the carbon-based materials.

This traditional process requires very high temperatures above 800 degrees Celsius and strong reagent chemicals for pretreatment.

With their ability to store relatively large amounts of power, supercapacitors can play an important role in making renewable energy sources practical for widespread deployment. They could provide grid-scale storage that could help match usage times with generation times, for example, or be used in electric vehicles and other applications.

The new devices produced by the MIT team already match or exceed the performance of existing carbon-based versions in key parameters even without any optimization of their characteristics.

The parameters include their ability to withstand large numbers of charge/discharge cycles. Tests showed they lost less than 10 percent of their performance after 10,000 cycles, which is comparable to existing commercial supercapacitors.

"Our lab's discovery of highly electrically conductive MOFs opened up a whole new category of applications," according to Dincă.

Besides the new supercapacitor uses, the conductive MOFs could be useful for making electrochromic windows, which can be darkened with the flip of a switch, and chemoresistive sensors, which can be useful for detecting trace amounts of chemicals for medical or security applications.

This discovery is "very significant, from both a scientific and applications point of view," said Alexandru Vlad, a professor of chemistry at the Catholic University of Louvain in Belgium, who was not involved in this research.

He noted that "here is the breakthrough provided by Dinca et al. They could design a MOF with high surface area and high electrical conductivity, and thus completely challenge the supercapacitor value chain! There is essentially no more need of carbons for this highly demanded technology."

The research team included former MIT postdoc Dennis Sheberla (now a postdoc at Harvard University); MIT graduate student John Bachman; Joseph Elias PhD '16, and Cheng-Jun Sun of Argonne National Laboratory.

The work was supported by the U.S. Department of Energy through the Center for Excitonics; the Sloan Foundation; the Research Corporation for Science Advancement; 3M and the National Science Foundation.