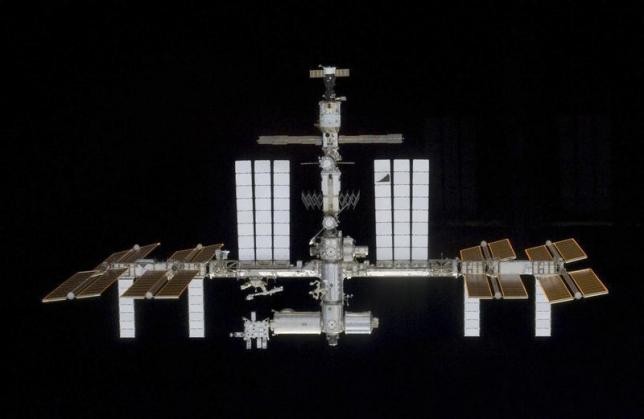

With China's plans to launch its space station Tiangong-2 in 2016, there has been rigorous efforts to provide astronauts that would be participating in the space program the best tools and equipment in the most efficient way possible.

As such, a recent research facility under the China Aerospace Science and Technology Corporation has proposed and tested the use of the newest 3D printing technology to accomplish such feat.

Among the first few innovations to be produced in this revolutionary way are the vent pipes and the flanges connecting the pipes used on extravehicular space suits. These 3D-printed parts improve the quality of the suits, making them more reliable and safer for the astronauts to use.

The 3D printing technology used to develop the space suit parts is similar to the one available at the Shanghai Academy of Spaceflight Technology. Wang Lianfeng, a senior engineer at the institute, explained the necessity of 3D printer for space missions:

"It's very difficult to process the complicated parts by traditional methods. For example, it takes two groups of workers, working shifts around the clock, more than two weeks to make a part of a rocket engine, but a 3D printer can do it in just 16 hours," said Lianfeng.

While Chinese 3D technology is at the forefront of innovation, there is still much left to be desired from the accuracy and the precision of the device.

According to Lianfeng, researchers are laboring to find the best material and to develop the best printer to aid in these space efforts.