Scientists have revealed a new method in 3D printing that can create flexible ceramic based structures that possess incredible strength including significantly less porous qualities and cracking characteristics.

This new method maximizes the qualities of polymer and ultraviolet light in never before seen ways before, more specifically in high temperature settings that ranges from micro electrical mechanical devices to jet engines, according to this new research.

Three dimensional ceramic printing can bring about huge potential as it can provide possibilities in creating complex shapes with no moveable parts that can be challenging to produce using traditional manufacturing methods.

When it comes to manufacturing ceramics, the most common techniques involve additives with layer by layer selective curing of powder based precursors that are deemed to be extremely slow processes, also creating products with high porosity and more cracks, that tends to weaken the final product.

Now, researchers from HRL Laboratories in California explored a new and better approach from prior developments that deal with ceramic polymer chemistry and UV light control when it comes to the additive manufacturing process.

Researchers then fixed the chemistry of these inorganic preceramic monomers that have been used for decades to synthesize ceramic fiber and other similar materials in order for the monomers to mesh into polymer chains upon UV light exposure.

Scientists experimented with several approaches where they manufactured a resin via UV techniques with preceramic monomers where one method involved UV light reflected and concentrated into the ceramic polymer as a byproduct of polymerization from the monomer additives.

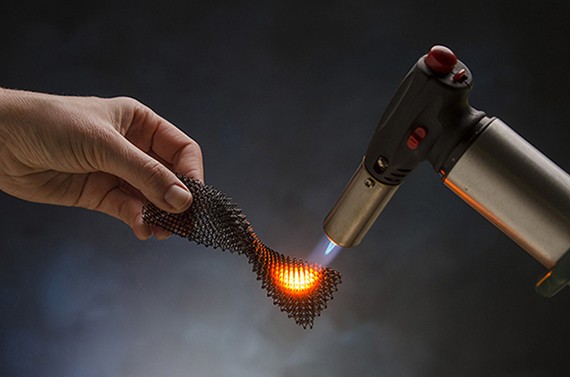

The final printed polymer is then heated up to 1,000 degrees Celsius with inert argon gas that can drive away many remaining volatiles which only leaves behind a pure ceramic part.

Electron microscopy reveals that this flexible and surprisingly strong 3D printed ceramic component contains only little or no porous qualities at all and even cracking, that can also withstand extreme temperatures of 1,400 degrees Celsius without any signs of degrading.

This new study is published in the journal, Science.