Researchers at Chalmers University of Technology in Gothenburg, Sweden have developed the basis for a new and bendable electronic paper that also consumes incredibly small amounts of energy.

This new type of electronic paper is less than a micrometer thin; is flexible and emits all the colors a regular LED display does. But, more important, this electronic paper only needs 10 times less energy than a Kindle tablet.

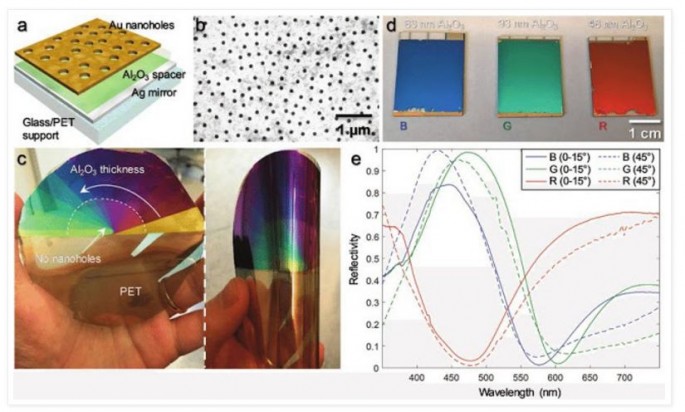

Andreas Dahlin, Assistant Professor at Chalmers, and his Ph.D. student, Kunli Xiong, discovered that the combination of conductive polymers on nanostructures are perfectly suited to creating electronic displays as thin as paper.

The material they described in a research paper published in the journal, Advanced Materials, works very well in bright light in contrast to standard LED displays that work best in darkness, said Dahlin.

"At the same time it needs only a tenth of the energy that a Kindle tablet uses, which itself uses much less energy than a tablet LED display," noted Dahlin.

"The 'paper' is similar to the Kindle tablet. It isn't lit up like a standard display, but rather reflects the external light which illuminates it."

He said the electronic paper's qualities all depend on the polymers' ability to control how light is absorbed and reflected. The polymers that cover the whole surface transmit electric signals throughout the full display and create images in high resolution.

The material isn't yet ready for application, however, but the basis is there, said Dahlin.

The team has tested and built a few pixels using the same red, green and blue (RGB) colors that together can create all the colors in standard LED displays. The results so far have been positive.

What remains to be done, however, is to build pixels that cover an area as large as a display.

"We are working at a fundamental level but even so, the step to manufacturing a product out of it shouldn't be too far away. What we need now are engineers," according to Dahlin.

One obstacle is the need to use gold and silver in the display.

"The gold surface is 20 nanometers thick so there is not that much gold in it. But at present, there is a lot of gold wasted in manufacturing it. Either we reduce the waste or we find another way to reduce the production cost."

Dahlin thinks the best application for the displays will be in well-lit outdoor locations. This could reduce energy consumption while replacing signs and information screens that aren't electronic.